No matter where you live, if your vehicle’s A/C compressor is not turning on, it can turn a pleasant commute into a nightmare (particularly if you have kids).

The A/C compressor pulley is always being turned by either the serpentine belt or a dedicated belt. It uses a clutch to grab the pulley and cycle coolant through the system. It is this clutch that causes an A/C compressor not to turn on.

Before opening the hood to see if there is anything wrong with the A/C compressor, start the car and turn the A/C off and back on a few times.

If you hear a “thunk” or “clunk” noise after turning the A/C on, the compressor is engaging. Something else is the problem. There’s most likely a leak, bad evaporator, or a bad compressor (that is engaging).

Here’s how to about diagnosing why the

1. Inspect the Belt

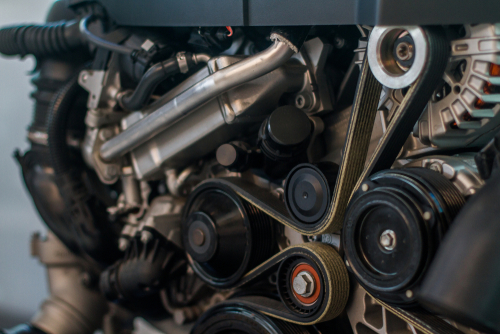

As stated above, the A/C compressor may be turned by the serpentine belt that turns all of the engine accessories. Or, it may be turned by an independent belt. If there are two belts, they’ll both be attached at the crank pulley.

Inspect the belt to see if it is cracked or shiny. It may just be that the belt can’t turn the compressor anymore. It could even be missing entirely without you noticing if it is an independent belt.

After inspecting the belt, there can only be two things left that could be happening:

1. The clutch is not getting a signal to turn on. This indicates some form of wiring problem.

-or-

2. The A/C compressor is getting a command to turn on but is no longer able to, which would indicate that it needs replacing.

2. Turn the Compressor by Hand

The A/C compressor should freely turn by hand when it is not engaged. Obviously, you’d want to do this with the vehicle off. It’ll often be located by electric fans. Even with the key off, treat them like they can still come on.

You don’t want to turn the pulley where it is attached to the belt. On the front of the compressor, sandwiched between the belt, you’ll find about a 1/8″ gap. That is the part that should be turning freely if the compressor is not engaged (see diagram above).

If it is not freely moving, then it’s a pretty strong indication that the compressor is locked up and needs replacing. On the other hand, if it is turning freely, we need to determine why it’s not activating.

3. Check the Wiring Harness

Being that the clutch compressor is just a few feet off of the road, it can accrue wiring damage over the years.

Inspect the harness to make sure that it doesn’t have any opens or shorts. If it looks good, it’s time to move on to testing the relay and seeing if you can manually get the compressor to turn on.

The power going to the A/C compressor relay is going to be fused, so check that fuse while you’re at it as well. You can do this in under 2 minutes with a test light.

4. Test the Compressor Clutch

You can use a jump wire to determine if the compressor clutch is activating properly. But, first, you’ll need to locate the compressor relay.

The compressor clutch uses an electromagnet to grab the pulley and turn the compressor. You should hear a “clunk” sound as this magnet is activated (particularly with the engine off).

You’ll need a jump wire. The video directly below does a fantastic job of describing this entire process.

Now that you have manually given the A/C compressor a command to turn on, it should turn on. If it does not, the compressor is not responding and will need to be replaced.