Some engines are built to run. Others are built to prove a point. These mechanical marvels pushed the limits of engineering, performance, and sometimes, common sense.

From 16 cylinders to turbo-mad science, here are the most complicated engines ever dropped into a car… because simple just wouldn’t cut it.

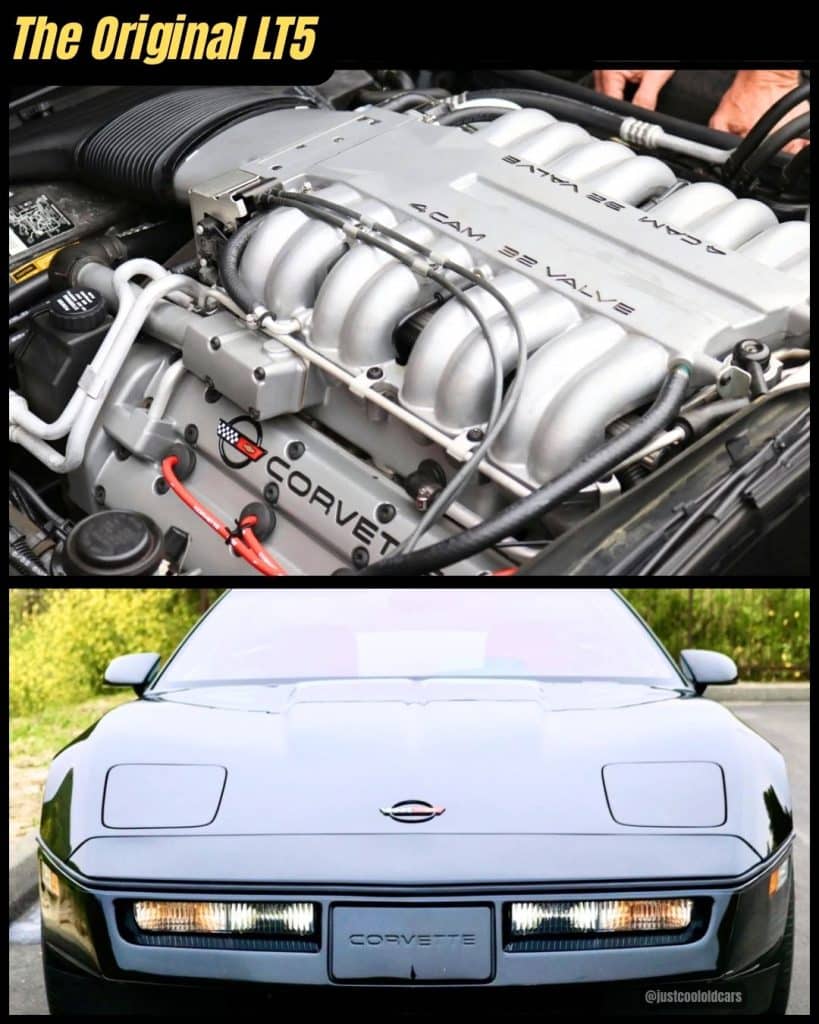

1. Chevrolet LT5 (1990-1995)

- British brains, American muscle: Designed by Lotus and built by Mercury Marine in Stillwater, Oklahoma.

- Unique DOHC V8: It was the only dual overhead cam engine in a Corvette until the C8 Z06 in 2023.

- Hand-built engine: Every LT5 was assembled by hand, one at a time.

The 1990-1995 Chevrolet LT5 was a moonshot for GM. Designed to give the Corvette a world-class engine, GM tapped Lotus for engineering and Mercury Marine for production.

They came up with a wild combo that screamed, “Spare no expense!” The result? A 5.7L aluminum-block V8 with dual overhead cams and 32 valves that revved to 7,200 RPM, a huge leap from the typical small-block Chevy you’d find under the hood of a new Corvette.

It powered the legendary C4 ZR-1, a ‘King of the Hill’ Corvette that embarrassed Ferraris and Porsches of the day.

The LT5 made 375 hp at launch and 405 hp by 1993- numbers that blew minds in the early ’90s.

But its complexity and cost killed it. Parts weren’t interchangeable with standard small blocks, and it required special tooling and expertise to work on.

It was a bold move by GM, one that proved they could build an exotic-level engine, but it was too far ahead of its time for most mechanics and too pricey for the average Corvette buyer.

Still, it remains a high-water mark in GM’s performance history.

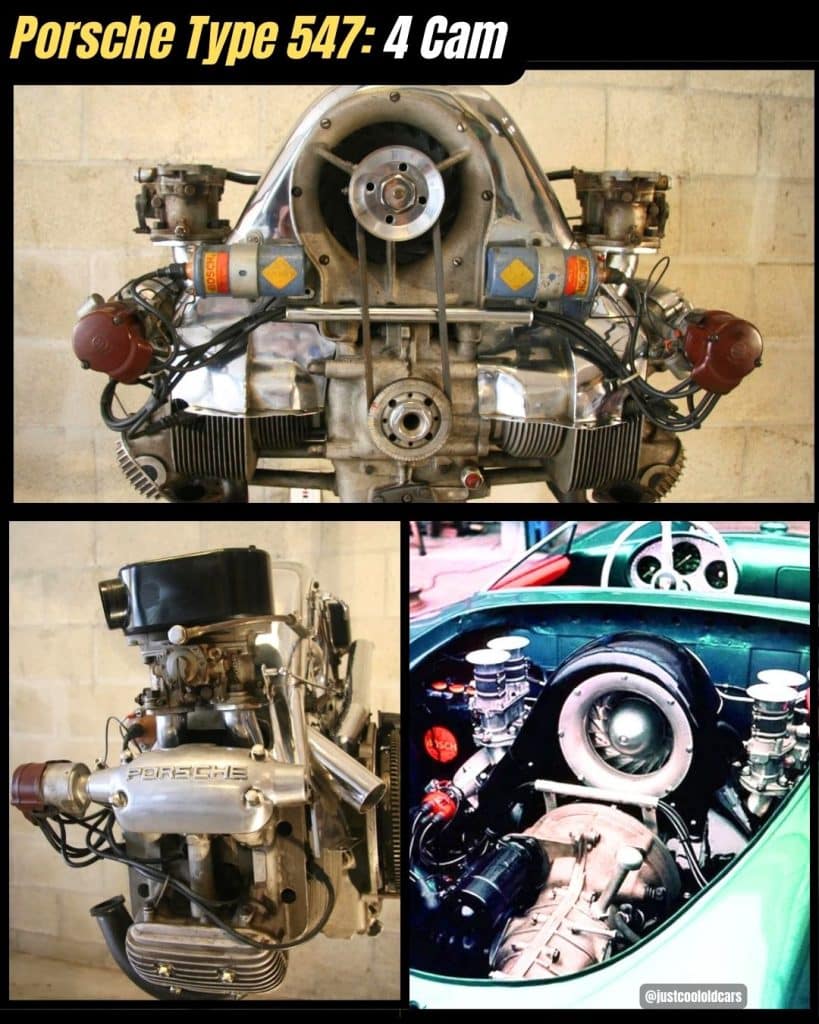

2. Porsche Type 547 (1953–1964)

- Nicknamed the “Fuhrmann engine”: Named after Dr. Ernst Fuhrmann, the genius who designed it for Porsche’s race program.

- Gear-driven cams: Instead of using chains or belts, the 547 used a complex gear train to spin its four camshafts.

- Hand-assembled in a clean room: Each engine took over 120 hours to build and was usually only touched by one technician from start to finish.

The Porsche Type 547 was a masterpiece of overengineering that powered legends like the 550 Spyder and early 356 Carreras.

It was a 1.5L flat-four, air-cooled engine with four overhead camshafts, two spark plugs per cylinder, and dual distributors. All of that packed into an engine that could sit in a carry-on suitcase.

It was a technical marvel, but also a mechanic’s nightmare. The gear-driven cams were precise, but nearly impossible to time without specialized tools.

The tolerances were so tight that even seasoned Porsche techs had to approach it like surgery.

The 547 wasn’t built for ease- it was built to win. And win it did, powering Porsche’s rise in international racing.

But it was so complex and expensive that Porsche later simplified their engine designs just to make production viable.

In the world of engines, the Type 547 was the Swiss watch: stunning, intricate, and brutally unforgiving.

3. Oldsmobile Turbo Rocket (1962-1963)

- World’s first turbocharged production car engine: Debuted in the 1962 Oldsmobile Jetfire, paired with a high-tech (and finicky) fluid injection system.

- Used “Turbo-Rocket Fluid”: A special water-methanol mix that drivers had to refill manually or risk engine damage.

- Only 5,000 built: It was too advanced and unreliable for the average American car buyer in the early ’60s.

The Oldsmobile Turbo Rocket was a bold experiment that arrived way before the world was ready.

Dropped into the sleek, aluminum-bodied Jetfire, this 215 cubic inch V8 came with a Garrett turbocharger and pumped out 215 horsepower per cubic inch, a big deal back then.

But Oldsmobile knew detonation would be an issue, so they added a fluid injection system called “Turbo-Rocket Fluid”: a cocktail of distilled water, methanol, and corrosion inhibitor that cooled the intake charge and controlled knock.

If the fluid ran low, the turbo system shut itself down.

Drivers hated it. They forgot to refill the fluid. The turbo setup was delicate. And most dealerships didn’t know how to service it.

In the end, Olds ripped the turbos out of most Jetfires and retrofitted them with a regular carb setup.

It was a wild piece of engineering, packed with innovation, but way too complex for 1962. Still, it laid the groundwork for turbocharging in American cars long before the technology caught on.

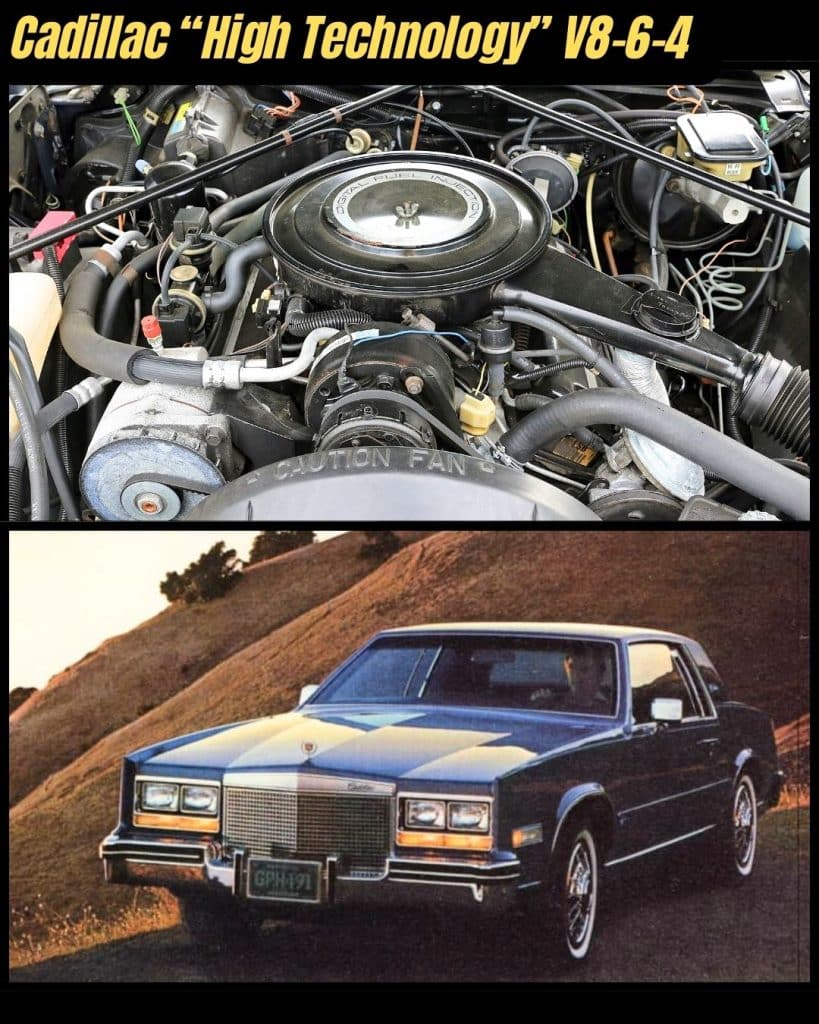

4. Cadillac V-8-6-4 (1981)

- Cylinder deactivation in 1981: It could shut off 2 or 4 cylinders under light load to save fuel, decades before it became common.

- Controlled by a primitive computer: The system relied on early ECM tech that simply wasn’t ready for the job.

- Only lasted one model year: Cadillac dropped it after endless complaints and dealership headaches.

The Cadillac V-8-6-4 was a fuel-saving idea ahead of its time-but the tech wasn’t there yet.

Using solenoids and an early engine control module, the 368-cubic-inch V8 could deactivate cylinders when cruising, running as a V6, or even a V4 to boost mileage.

In theory, it was genius. But the electronics were crude, and drivers experienced constant hesitation, surging, and rough shifts. Mechanics didn’t know what to do with it, and most owners eventually had the system disabled.

It was a noble failure-flawed but visionary-and it paved the way for the reliable cylinder deactivation systems we know and hate today.

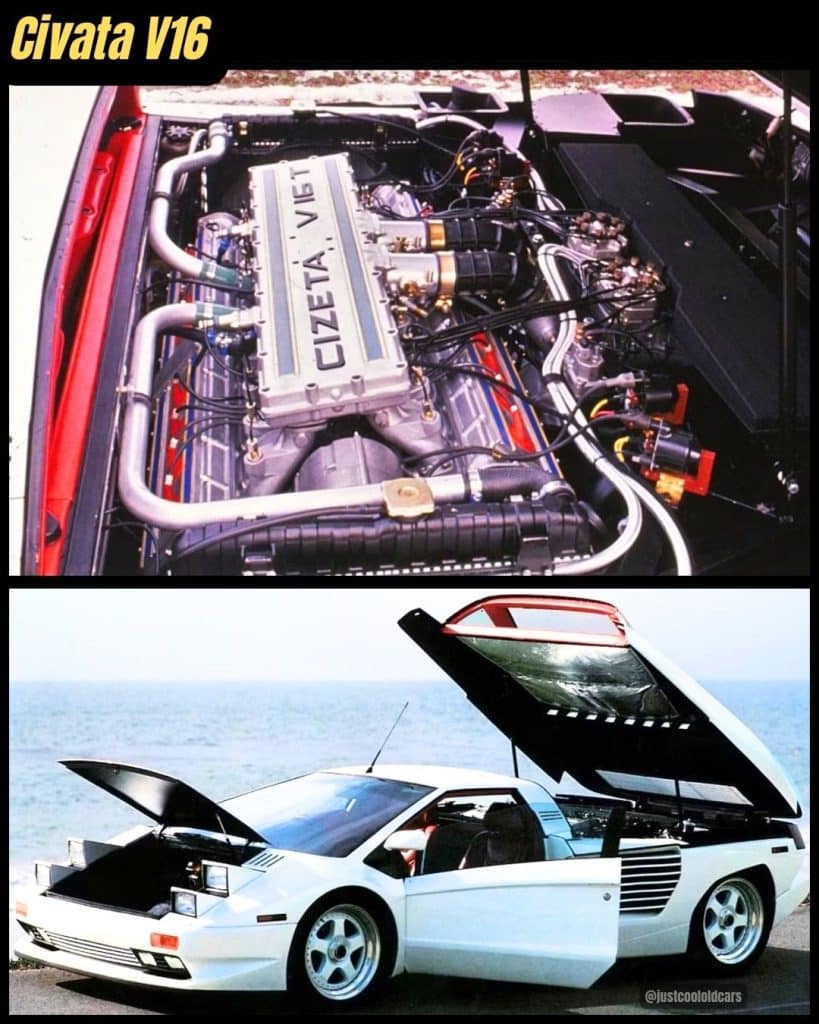

5. Cizeta V16T (1991-1995)

- True V16 engine: Built by joining two Lamborghini V8s on a single block, and yes, it had 16 cylinders.

- Transversely mounted: The massive V16 sat sideways behind the driver, making the car absurdly wide.

- Designed by ex-Lambo talent: Engineered by Claudio Zampolli and styled by Marcello Gandini, the man behind the Miura and Countach.

The Cizeta V16T was a supercar fever dream. Under its clamshell rear sat a 6.0L V16 with eight camshafts and 64 valves, paired to a transverse 5-speed gearbox.

It made 540 horsepower and howled like two Countachs screaming in harmony.

But this thing was an engineering nightmare. The V16 was heavy, complex, and expensive to produce.

Cooling was always a problem. And being hand-built in tiny numbers, reliability was more hope than guarantee.

Only a handful were ever made. But it remains one of the most jaw-droppingly overcomplicated engines to ever hit the road: pure 1990s excess, engineered without a care for practicality.

6. Bugatti W16 (2005-2023)

- Quad-turbo, 16 cylinders, 64 valves: It was basically two narrow-angle V8s fused together on a common crankshaft.

- 1,000+ horsepower from day one: The original Veyron version cranked out 1,001 hp, no mods needed.

- Built for 250+ mph: The engine wasn’t just powerful, it was designed to run flat-out for minutes at a time.

The Bugatti W16 was one of the most ambitious and overengineered powerplants ever stuffed into a production car.

Built for the Veyron and later the Chiron, it packed quad turbos, four camshafts, and a complex cooling system with 10 radiators.

It was a technical masterpiece, but wildly complex. The engine alone reportedly cost over $250,000 to build.

Each one was hand-assembled in Germany and had to meet insane standards, because Bugatti promised customers they could run 250 mph without the thing melting down.

It was absurd, excessive, and flawless- and that’s what made it unforgettable.

7. Saab Two-Stroke Triple (1950-1968)

- No valves, just ports: Like a chainsaw or dirt bike, it used intake and exhaust ports instead of valves.

- Ran on oil-mixed fuel: Drivers had to mix oil with gas or risk seizing the engine.

- Freewheeling clutch: It coasted without engine braking to prevent oil starvation on deceleration.

The Saab Two-Stroke Triple was simple in design but tricky in practice.

This 3-cylinder, 2-stroke engine powered early Saabs like the 92, 93, and 96. It was compact and lightweight, perfect for front-wheel drive, but it demanded constant attention.

Because it was a 2-stroke, you had to mix oil with the fuel. Forget once, and you could ruin the engine.

It also had a unique freewheel mechanism, so when you let off the gas, the engine disengaged from the wheels to avoid running lean and seizing.

It made a charming buzz and was surprisingly quick for its size, but it smoked like a barbecue and hated modern traffic.

Quirky, smoky, and unforgettable, it was a little engine with a lot of personality.

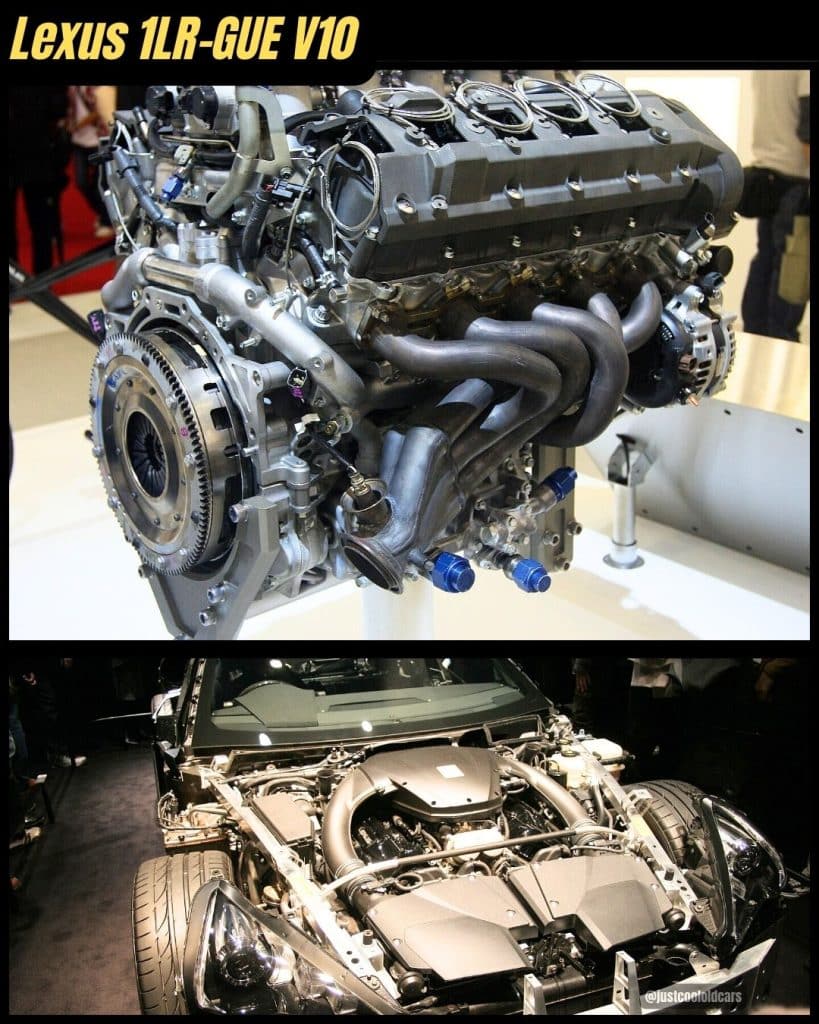

8. Lexus 1LR-GUE V10 (2010-2012)

- Inspired by F1 tech: This 4.8L V10 could rev from idle to 9,000 RPM in just 0.6 seconds.

- Digital tachometer required: It revved so fast that an analog needle couldn’t keep up.

- Built almost entirely from aluminum, magnesium, and titanium: Light, exotic, and hand-assembled by Yamaha’s best.

The Lexus 1LR-GUE V10 was Japan’s answer to Ferrari-a naturally aspirated masterpiece stuffed into the Lexus LFA supercar.

Compact as a V8 and light as a V6, it used exotic metals and precision engineering to deliver 552 horsepower and a soundtrack that echoed Formula 1’s golden era.

But it was wildly overbuilt. Titanium rods, a dry-sump oil system, custom intake tuning- it was more race engine than road engine, with a price tag to match.

Each motor was built in a climate-controlled room, and only 500 LFAs were ever made.

It was too complicated to mass-produce, but for those lucky few-it was the soul of a supercar.

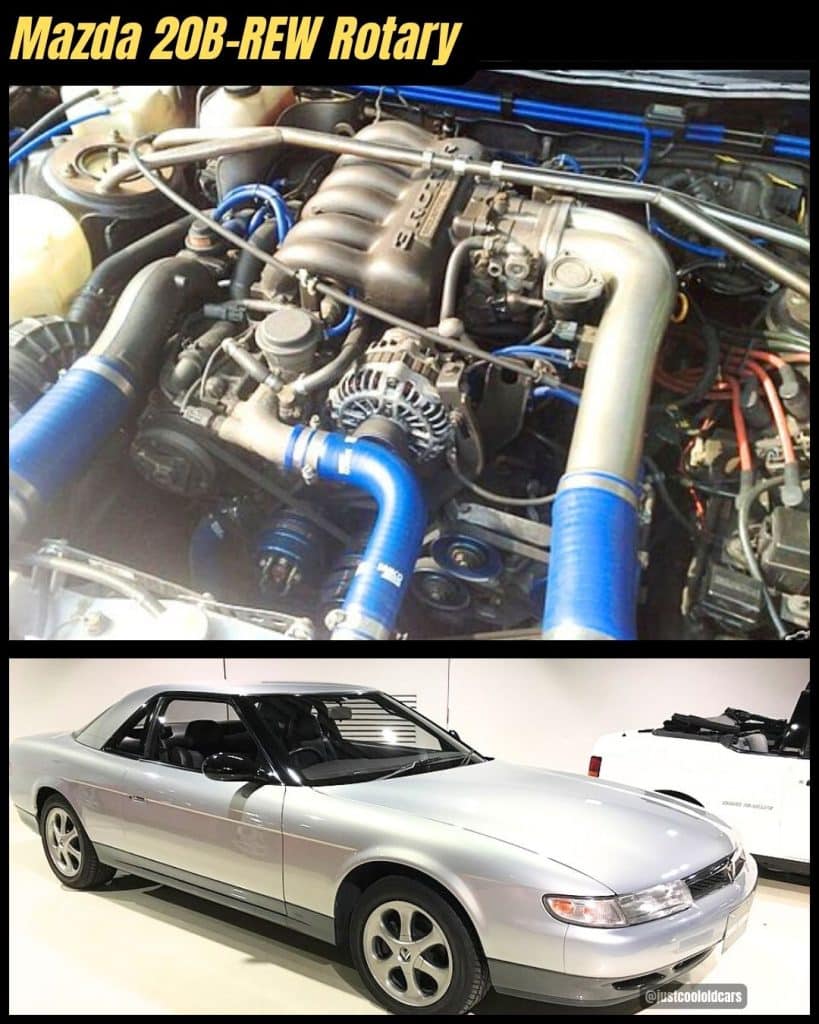

9. Mazda 20B-REW Rotary (1990-1995)

- Three rotors, twin turbos: The only production 3-rotor rotary engine ever offered by Mazda, with sequential turbocharging.

- No pistons, no valves: Like all rotaries, it used spinning rotors in a housing shaped like a peanut.

- Powered the Japan-only Eunos Cosmo: A luxury coupe that could hit 155 mph in comfort and silence.

The 20B-REW was Mazda’s most ambitious rotary engine, featuring three rotors and a twin-turbo setup that delivered a silky 276 horsepower.

It used sequential turbocharging, one turbo for low RPM, the other kicking in up high for a smooth, relentless pull.

But with that performance came complexity. It had a high-maintenance appetite for oil, poor fuel economy, and sealing issues that plagued even well-maintained engines.

And with three rotors spinning at over 8,000 RPM, heat management was a constant battle.

Exotic, smooth, and unlike anything else- the 20B was rotary engineering pushed to its extreme.

10. BRM H16 (1966-1968)

- Two engines in one: It was literally two flat-8s stacked on top of each other with dual crankshafts.

- Weighed nearly 500 pounds: Almost double the weight of rival engines-making it a nightmare for balance and handling.

- Won a single F1 race: Jim Clark drove it to victory at the 1966 US Grand Prix, one of the few times it didn’t break.

The BRM H16 is the kind of engine that could only come from Formula One’s anything-goes era.

Built to meet the new 3.0L rules, BRM didn’t go bigger- they went twice as complex.

The H16 was made by stacking two flat-8s, each with its own crankshaft, then tying them together through a gear train.

It made good power… when it ran. But it was insanely heavy, fragile, and a maintenance nightmare.

Teams fought oil leaks, overheating, and gear failures nearly every weekend. Most races ended with the engine in pieces.

A marvel of ambition and bad decisions, it remains one of the most fascinating failures in F1 history.

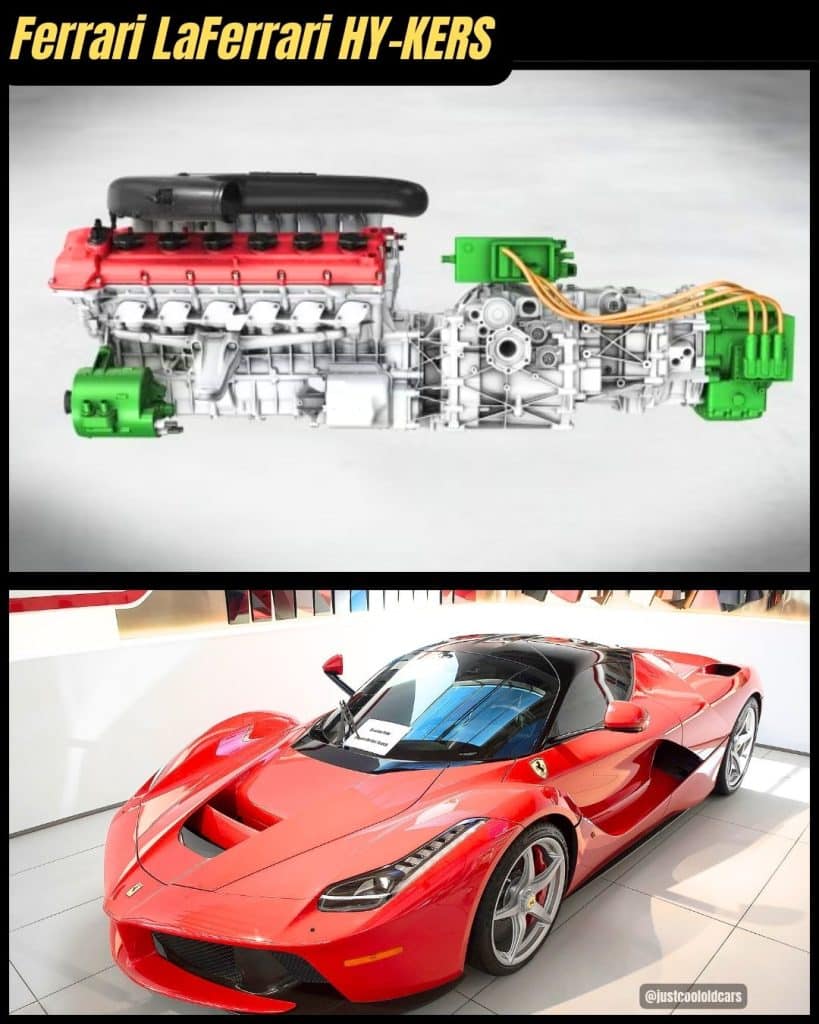

11. Ferrari LaFerrari HY-KERS (2013-2018)

- V12 + electric boost: Combined a 6.3L naturally aspirated V12 with a Formula One-style hybrid system.

- 963 total horsepower: The electric motor alone added 161 hp-no turbocharging required.

- No EV-only mode: The electric motor only worked with the gas engine-because Ferrari said it had to sound like a Ferrari.

The LaFerrari’s HY-KERS system was the most complicated drivetrain Ferrari had ever built. Under the hood sat a high-revving 6.3L V12, already a beast on its own.

But Ferrari wanted more, so they added an electric motor pulled straight from F1 tech, blending instant torque with old-school high-RPM fury.

But this wasn’t a Prius setup. The motor, batteries, inverter, and control systems had to work in perfect sync with a 9,000 RPM V12, without dulling the driving feel.

And the whole system had to stay lightweight, cool, and road-legal.

It was peak Ferrari: overly complicated, insanely fast, and built without compromise.

12.Volkswagen VR6 (1991–present)

- Single head for two banks: Used a 10.5°–15° V angle so both cylinder banks shared one head-ultra rare.

- Compact six-cylinder layout: Designed to fit transversely into front-wheel-drive cars without lengthening the engine bay.

- Weird firing order and sound: Known for its offbeat growl and unique intake harmonics.

The VR6 was Volkswagen’s answer to a problem: how do you fit six cylinders in a Golf-sized engine bay?

Their solution was to build a narrow-angle V6 that behaved like an inline engine, tucking six pistons into the space normally reserved for four.

It was clever-but also strange. The narrow V-angle meant uneven intake runners, odd cam profiles, and a lumpy power delivery that gave the VR6 its signature sound.

Cooling was tight. Timing chains were tricky. And tuning it was a specialized skill.

Still, it gave hot hatches like the GTI and Corrado a big dose of torque and personality earned cult status in the process.

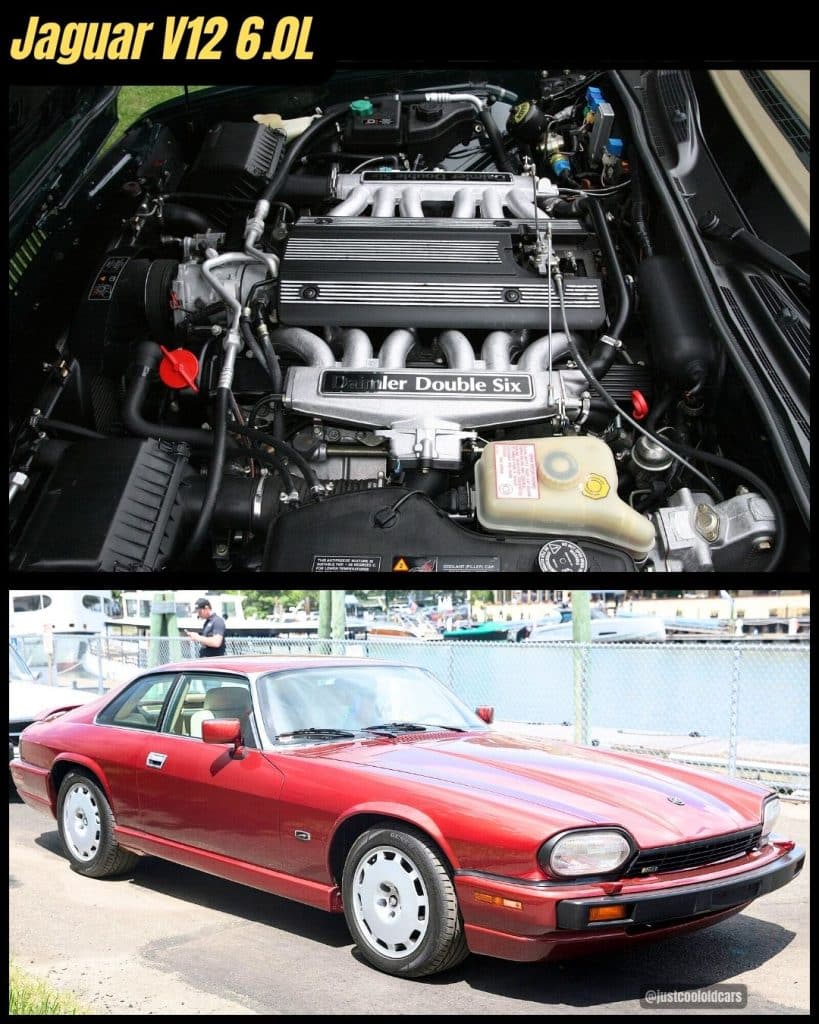

13. Jaguar V12 6.0L (1983–1997)

- Dual distributor setup: Used two distributors to fire twelve spark plugs-timing it was a chore.

- HE = High Efficiency: Introduced special swirl combustion chambers to balance power and emissions.

- Vacuum spaghetti nightmare: Vacuum lines ran everywhere, all essential to idle, timing, and emissions.

Jaguar’s 6.0L V12 was the gentleman’s hot rod engine-smooth, powerful, and loaded with engineering quirks.

Originally a 5.3L, the 6.0L High Efficiency (HE) version cranked out more torque and better mileage, thanks to a redesigned head with swirl-inducing combustion chambers.

But it came at a cost. The dual distributor ignition system was notoriously hard to set up, and a jungle of vacuum hoses controlled everything from idle to advance timing.

If just one cracked, the whole system could fall on its face.

When it ran right, it was silk. When it didn’t, it tested your faith. A beautiful disaster that made you work for every mile.

14. BMW N73 V12 (2003–2015)

- Valvetronic and VANOS together: Combined variable valve lift and variable cam timing-rare on any engine, let alone a V12.

- No throttle body at all: Used electronic valve lift to control air flow, not a traditional throttle plate.

- Powered by the BMW 760Li: Silky smooth with over 430 hp-but a maintenance minefield.

The BMW N73 V12 was built for quiet speed and technical bragging rights. With 48 valves, direct ignition, dual VANOS, and Valvetronic lift control, it delivered seamless torque and eerily silent acceleration, no throttle body needed.

But this level of precision required tight tolerances, finicky electronics, and complex diagnostics.

If something went wrong, good luck. Parts were expensive. Labor was worse. And not every BMW tech was trained to handle it.

It was a luxury V12 wrapped in computer code-and for the brave few, it was worth every penny and headache.

15. Mitsubishi 6A12 DOHC 24V (1992–2000)

- Narrow-angle design: Allowed a compact V6 to fit in small performance sedans and coupes.

- 24 valves with twin cams: Packed a full DOHC setup with tight camshaft phasing and tiny tolerances.

- High-revving but twitchy: Loved to scream past 7,000 RPM-but hated being out of tune.

The Mitsubishi 6A12 was a precision-built screamer that found its home in some of the coolest Japanese cars of the ’90s.

Despite its small 2.0L size, it featured dual overhead cams, four valves per cylinder, and tight packaging that squeezed it into a small FWD chassis without sacrificing power.

But that packaging brought problems. The cam phasing had to be dead-on, and any vacuum or ignition issue could throw it off. It was fast, but fragile, a mechanic’s puzzle with a redline payoff.

Not for the faint of heart-but when dialed in, it sang like few others in its class.

Thank you so much for reading!